1. SOAPSTONE (TALC)

- Raw Lumps

- Raw Powder

- Processed Fine Talc( 50-500 Mesh)

2. FELDSPAR

3. GROUNDED CALCIUM CARBONATE (GCC)

CONTROLLED PSD PRODUCTS:-

- GCC 400

- GCC 600

- GCC 800

- GCC 1500

- GCC 2500

4. MAGNESITE

- Raw Magnesite

- Magnesium Carbonate Powder

- Dead Burnt Magnesite (DBM)

- Caustic Calcined Magnesite (CCM)

- Magnesium Carbonate

5. GRANITE

6. QUARTZ

SOAPSTONE (TALC)

Talc is a versatile mineral, widely used in various industrial applications. The nature of deposit, formation of Talc is the index of its chemical purity and physical features. Important properties of Talc are its chemical inertness, high dielectric strength, high thermal conductivity, low electrical conductivity and oil & Greece absorption. Asif Chemicals produces one of the best quality Talc from our own mines, which is free of any types of bi-minerals, like silica and asbestos and hence require no further purification. Talc Lumps are used in many industries, including paper making, plastic, paint and coatings, rubber, food, electric cable, pharmaceuticals, cosmetics, and ceramics. A coarse grayish-green high-talc rock is soapstone or steatite, used for stoves, sinks, electrical switchboards, crayons, soap. Blanc Fixe Talc lumps finds use as a cosmetic (talcum powder), as a lubricant, and as a filler in paper manufacture. It is used to coat the insides of inner tubes and rubber gloves during manufacture to keep the surfaces from sticking. Talc, with heavy refinement, has been used in baby powder.

FELDSPAR

Feldspar is the name given to a group of minerals distinguished by the presence of alumina and silica (SiO2) in their chemistry. This group includes aluminum silicates of soda, potassium, or lime. It is the single most abundant mineral group on Earth. They account for an estimated 60% of exposed rocks, as well as soils, clays, and other unconsolidated sediments, and are principal components in rock classification schemes. The minerals included in this group are the orthoclase, microcline and plagioclase feldspars.

GROUNDED CALCIUM CARBONATE (GCC)

Grounded Calcium Carbonate is processed through naturally occurring high purity calcite ores containing CaCO3 as major component. The selected raw material has to be washed, crushed ,fine gridded and then classified precisely to attain the products of exceptional consistent & desirable quality available in a variety of grades. A dry process line (GCC), involves a series of crushing and fine milling stages that produces a fine (micronized) product. During the processing, the material is processed & classified in dry form to attain the desired quality of the products. The fineness (D 50) of the standard products thus obtain is (1-5) microns. Calcium carbonate appears as white, odorless powder or colorless crystals. Practically insoluble in water. Occurs extensive in rocks world-wide. The extraction process keeps the carbonate very close to its original state of purity and delivers a finely ground product either in dry or slurry form. The main use of calcium carbonate is in the construction industry, either as a building material, or limestone aggregate for road building, as an ingredient of cement, in the purification of iron from ore in a blast furnace, added to swimming pools, as a pH corrector for maintaining alkalinity, raw material in the refining of sugar from sugar beet, form of chalk has traditionally been a major component of blackboard chalk, widely used as an extender in paints, In ceramic glaze applications, calcium carbonate is known as whiting,

MAGNESITE

Magnesite is a magnesium carbonate mineral with a chemical composition of MgCO3. It is named after the presence of magnesium in its composition. Magnesite usually forms during the alteration of magnesium-rich rocks or carbonate rocks by metamorphism or chemical weathering.

There are two main uses for Magnesite. The first is as feedstock in the production of dead-burned magnesia and for refractory brick use in lining furnaces in the steel industry and non-ferrous metal processing units and cement kilns. The second use is for processing to caustic calcined Magnesia which is used principally as a food supplement in agribusiness and in fertilizers as well for fillers in paints, paper and plastics. Raw Magnesite is used for surface coatings, landscaping, and ceramics and as a fire retardant.

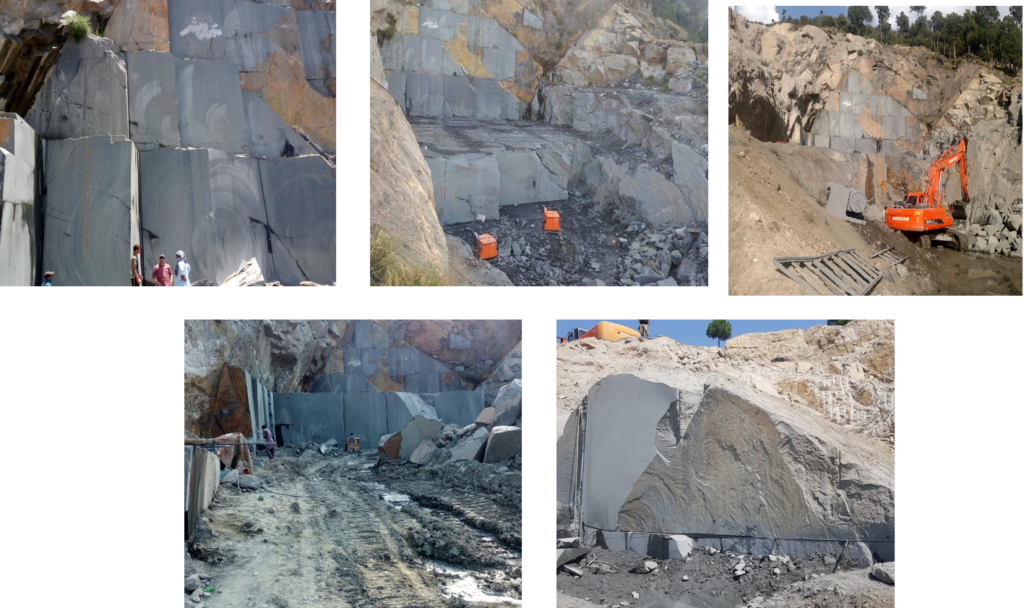

GRANITE

Granite is a light-colored plutonic rock found throughout the continental crust, most commonly in mountainous areas. It consists of coarse grains of quartz (10-50%), potassium feldspar, and sodium feldspar. These minerals make up more than 80% of the rock. Other common minerals include mica (muscovite and biotite) and hornblende (see amphibole). The chemical composition of granite is typically 70-77% silica, 11-13% alumina, 3-5% potassium oxide, 3-5% soda, 1% lime, 2-3% total iron, and less than 1% magnesia and titania. Volcanic rock of equivalent chemical composition and mineralogy is called rhyolite. Granites are the most abundant plutonic rocks of mountain belts and continental shield areas. They occur in great batholiths that may occupy thousands of square kilometers and are usually closely associated with quartz monzonite, granodiorite, diorite, and gabbro.

QUARTZ

Quartz is one of the most common minerals in the Earth’s crust. As a mineral name, quartz refers to a specific chemical compound (silicon dioxide, or silica, SiO2), having a specific crystalline form (hexagonal). It is found in all forms of rock: igneous, metamorphic and sedimentary. Quartz is physically and chemically resistant to weathering. When quartz-bearing rocks become weathered and eroded, the grains of resistant quartz are concentrated in the soil, in rivers, and on beaches. The white sands typically found in river beds and on beaches are usually composed mainly of quartz, with some white or pink feldspar as well.